Building a Cleaner Future

SAFE AND NON-DESTRUCTIVE REMOVAL OF PFAS

Soil • Sludge • Colloids • Fluids • Surfaces • Objects • Air

SAFE AND NON-DESTRUCTIVE REMOVAL OF

PER AND POLYFLUOROALKYL SUBSTANCES (PFAS)

RHEOLOGY BASED REMOVAL TECHNOLOGY

“You’ve got to start with the customer experience and work backward to the technology.

You can’t start with the technology then try to figure out where to sell it.” — Steve Jobs

A PARADIGM SHIFT

Introducing a Revolutionary Approach to Environmental Remediation

Are you ready for a paradigm shift in environmental solutions? PFAS, the game-changer in contamination, demands a fresh perspective. At Ezra Terra we’ve reset the standard by erasing the chalkboard and starting anew.

Drawing from our extensive experience in private Brownfield restoration, we understand the value of complete site remediation. We’ve rescued properties for decades, disentangling them from regional groundwater and vapor plumes to unlock their full potential.

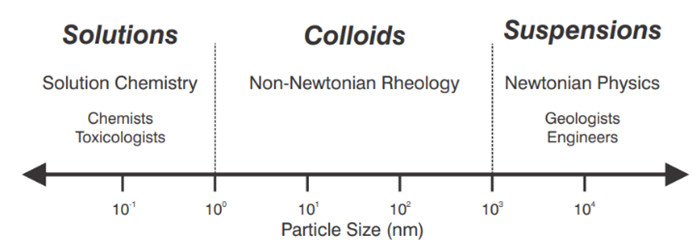

But PFAS is different. Its unique properties require a different approach, a new paradigm. That’s why we’ve delved deep into the “In Between” sciences, bridging the gap in professional licenses. Colloids and Non-Newtonian Rheology aren’t just buzzwords to us – they’re integral to understanding PFAS behavior.

Colloids, those tiny particles suspended in a medium, pose a challenge in traditional remediation methods. And PFAS? It goes a step further, forming microemulsions – complex “Surfactant-Water Oil” systems that defy conventional solutions.

At Ezra Terra, we’re not just adapting – we’re innovating. Our cutting-edge techniques and interdisciplinary expertise redefine what’s possible in environmental remediation. Join us in reshaping the future of clean-up and restoration. Together, let’s tackle PFAS head-on and pave the way for a healthier, safer tomorrow.

PFAS ANALYSIS AND SAMPING

At Ezra Terra, we’ve delved deep into the intricate realm of PFAS, where its complex chemical system manifests as unique films in nature. Through innovative techniques, we’ve mastered the art of manipulating these amphiphilic films, seamlessly transporting them, altering their states, and even reversing the process.

Our journey has led us to gain intimate knowledge of the subsurface structures of PFAS in groundwater sources. This expertise equips us to navigate and mitigate PFAS contamination effectively, ensuring the health and safety of our environment and communities.

Join us as we continue to unravel the mysteries of PFAS and lead the way towards sustainable solutions for a cleaner, healthier world.

CLEAN UP AND REMEDIATION CHALLENGES

Elevate Your Site Remediation Efforts with Our Expert Object Decontamination Services

When it comes to achieving site closure, every detail matters – including the cleanliness of your investigation and remediation tools. At Ezra Terra, we specialize in object decontamination, ensuring that metallic implements essential for your projects are free from harmful PFAS films.

Unlike traditional methods that may fall short, our advanced techniques are tailored specifically for PFAS removal, guaranteeing thorough and effective decontamination. Whether it’s metallic implements, drilling and excavation tools, or dump truck beds, we’ve got you covered.

Trust us to elevate your remediation efforts with precision, reliability, and a commitment to environmental stewardship. Contact us today to learn more about how our object decontamination services can support your project’s success.

At Ezra Terra we specialize in the simultaneous treatment and removal of multiple contaminants, offering comprehensive solutions to address complex environmental challenges. Our co-contaminant treatment services are designed to effectively target and remediate a variety of contaminants, including petroleum hydrocarbons, chlorinated solvents, and PFAS.

Key features of our co-contaminant treatment services include:

We have the expertise to treat and

remove petroleum hydrocarbons and PFAS, as well as chlorinated solvents and

PFAS simultaneously. Our integrated approach ensures efficient and thorough

remediation of co-occurring contaminants.

In situations where contaminants are

present at high concentrations, we employ fractional treatment techniques. This gradual increase in application temperature allows for safe and orderly contaminant treatment and removal, minimizing risks and ensuring effective

results,

Former Wurtsmith AFB AFFF Contaminated Soil Pile

The pile has been sitting at the former Wurtsmith AFB since 2019.

Togiak Alaska Soil Piles

The successful decontamination of the lighter soil pile stands as a shining example of Ezra Terra Inc's capabilities with our innovative system. We take pride in delivering effective solutions that ensure thorough cleaning and decontamination, demonstrating our commitment to excellence in environmental remediation.

At Ezra Terra, we understand the complexities of co-contaminant treatment and are dedicated to providing innovative solutions that meet the unique needs of each project. Trust us to deliver results that exceed your expectations, safeguarding the environment and the health of communities.

Contact us today to learn more about our co-contaminant treatment services and how we can assist you in achieving your environmental remediation goals!

Why we are different

A comprehensive, organized, scalable and deployable PFAS management program to deal with the entire lifecycle of waste.

We’ve developed a multi-media technology that can retrofit into existing waste infrastructure as well as investigate and clean-up PFAS spills. We recognize that the Carbon Fluorine bond is one of the strongest in nature. Breaking the bond produces Hydrofluoric Acid (HF), which is an extremely dangerous compound that can maim or kill a person. We safely remove PFAS and condense it to a salt powder. The PFAS salts are placed in a micro encapsulation vessel and disposed in a zero leachate hazardous waste landfill.

Our patented Sintered Wave Technology (SWT) Polarity Conversion is a comprehensive assemblage of technologies specifically designed for today’s regulatory setting and a wide variety of circumstances. It consists of:

1. On site treatment that can operate in non-attainment air basins

2. Safe, non-destructive removal of PFAS

3. 3D high resolution ground water source mapping and analysis

4. Removes PFAS from soil, sludge, colloids, fluids, surfaces, objects and air

Testimonials

“I met Patrick Brady 10 years ago facing an expensive T&D project. His proprietary thermal technology addressed a solvent cleanup with difficult subsurface conditions all on-site at a much lower cost than T&D. After that initial success, we completed two similar projects including a 100,000 ton Brownfield project under the strictest regulatory requirements allowing the client to meet a time sensitive transaction schedule.”

– Donald W. Moore, PG, ARM Environmental Risk & Financial Solutions

[In regards to his previous innovative thermal treatment technology used to remediate pure phase solvent (perchloroethylene) saturating an extremely dense clay (Bay Mud) in the San Francisco Bay Area] The project was an amazing success resulting in the complete on-site treatment of 2,500 tons of solvent-saturated clay to non-detect conditions. The project met and exceeded all key performance indicators originally set by the client and the regulatory agencies. The cost savings to the client were substantial because of avoiding the need to provide Class I hazardous waste disposal for this material. Additionally, lingering disposal liability was avoided leaving local city and regulatory officials pleased to avoid the hazards and local impacts that would have been associated with trucking the waste. A truly “green solution” to a very sticky problem.

–Paul D, Horton, Founder of The Source Group, Inc.

“Patrick is constantly innovating. He implemented technology enhancements on each subsequent project while managing project-specific permit and logistical challenges.”

– Donald W. Moore, PG, ARM Environmental Risk & Financial Solutions

“Mr. Brady’s commitment to excellence and to the project’s successful completion resulted in a big win for my client and for myself as project manager. I can highly recommend Mr. Brady and his technology approaches and am happy to provide direct reference to any person or entity considering working with EzraTerra.

As a result of this project, I have nothing but the utmost respect for his intellect, capabilities, commitment, and energy.”

– Paul D, Horton, Founder of The Source Group, Inc.

“Innovative Green Machine Cleans Dirt at Former Dry Cleaning Site”

– Santa Barbara Independent

“Breakthrough technology demonstrated in Klamath Falls”

– Klamath Explorer